So when I was building kit #72102, I had a pretty kickass shop. I have a 3-car garage and the shop was in the single car bay. It had multiple power outlets, compressor, band saw, drill press, giant 4’x12′ table, air conditioning, a TV for keeping me from getting bored, etc. I had to cut the table down to 2’x12′ when the wings were completed and the fuselage arrived. I kept that shop as a “shop” until November 2016 when I started construction on a “tactical teardrop camper“. Once the camper was completed, I never really put “the shop” back into shape because it’s where the camper was parked. Now that I’m back to being an airplane “builder” I had to make some logistical changes to get the shop back into shape.

Initially, I was unsure of how I wanted to approach this. But after I thought about it, I knew I wanted to be back in the shop for building. I needed a wall, air conditioning, power, air stations from the compressor, a TV, etc. This time I am going to find a simple 24″ interior door that someone is throwing out so I can use that for the shop.

The more things change…The more they stay the same

25 March 2019 – I cleaned out the east side of my garage and pulled the camper out of the single car bay. I moved the camper to the east side of the garage and squeezed it close to the wall so I can still have room to park the Pavement Princess. So the camper now resides on the east side of the garage and the shop restoration has begun. I still have a pile of wood scraps to dispose of and I need to build a couple of the EAA1000 construction tables. I am getting my shop back in order and that’s what counts.

27 March 2019 – I picked up a door from FB Marketplace. It’s not hung on a frame but that wasn’t really required. Now I will be able to close up the shop and help the A/C be more efficient.

13 April 2019 – I built two of the EAA1000 Construction Tables. They only took me about 8 hours total. I wasn’t working all that fast. Funny story, the EAA website gives you a materials list for two tables. I had intended to only build one table this weekend to see whether I liked them or not. So I printed the materials list and picked up the supplies at the aviation shop section of Lowes. As I’m sifting through the twisted 2×4’s looking for straight ones, I had to look again on the list. I got to thinking that this was a lot of wood for a table. So I got on the web and finally saw the part where this was supplies for two tables. No big. I built both tables. They turned out pretty amazing!

I did modify the design slightly. Instead of 21″ cross members, I did 17″ cross members so I could have a lip on the top surface for clamping. I also set one of the end cross members in so I could clamp on the end too. One end is flush with the end of each table so I could bolt the two tables together if need be. For the legs and doublers, I put the legs outside of the top frame and the doublers on the inside.

I want to start working on the wall tomorrow. I have a quick 5K event in the morning, so it’ll have be after that. I’ll need another 15 or so 2×4’s. I’ll have to decide on an A/C unit too because I need to do the rough opening for that when I frame up the wall.

14 April 2019 – I broke down and bought the wood for the wall and started putting that up. I decided on the A/C unit I’ll buy next month, so I did the rough-out for that and the door.

28 April 2019 – the shop is almost done! The wall is up, I have a TV in there along with a DirecTV receiver and the A/C is bought and waiting to be installed. I installed 8 T5 LED lights. These lights are pretty sweet and the shop has never been brighter! Holy crap its like daylight in the shop now. No dark spots. Here’s a link to the lights.

29 April 2019 – I still have to install the interior drywall pieces so I picked those up from Lowes today after work.

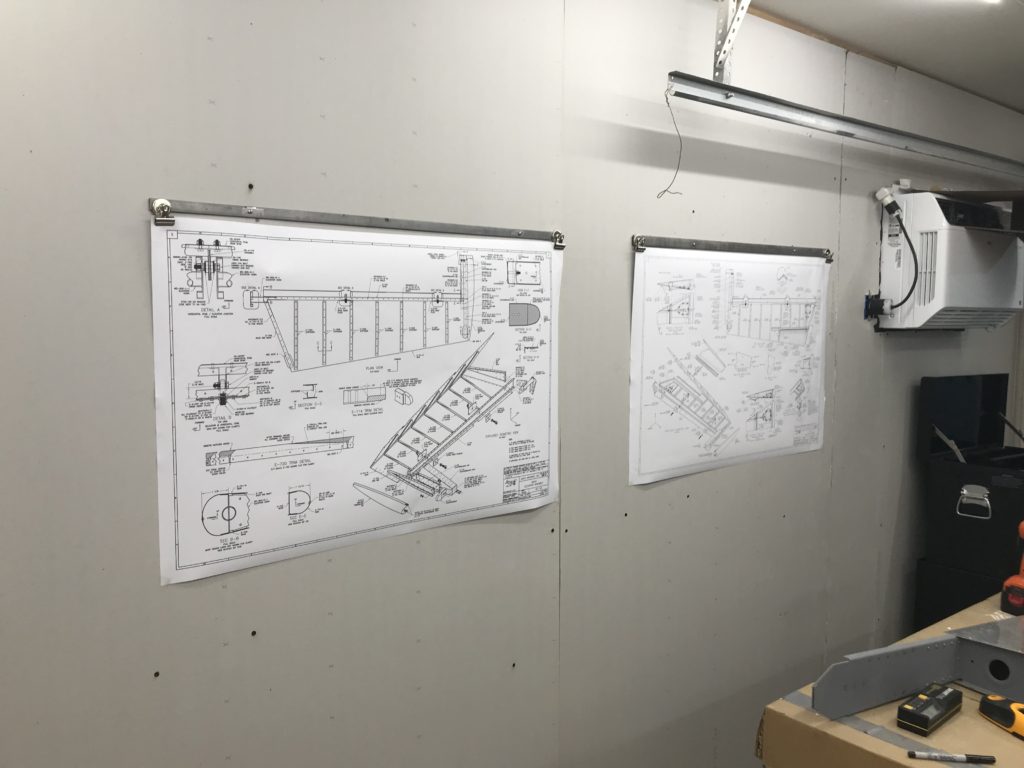

5 May 2019 – Happy Cinco DeMayo! I finally got the shop put together. The AC is cranking out cold air. I also added two spots to clip up the mechanical drawings. What I can’t believe is that the shop took so long to clean up after all was said and done. It took 14 hours total to get the inner drywall up, clean, and organize the shop.

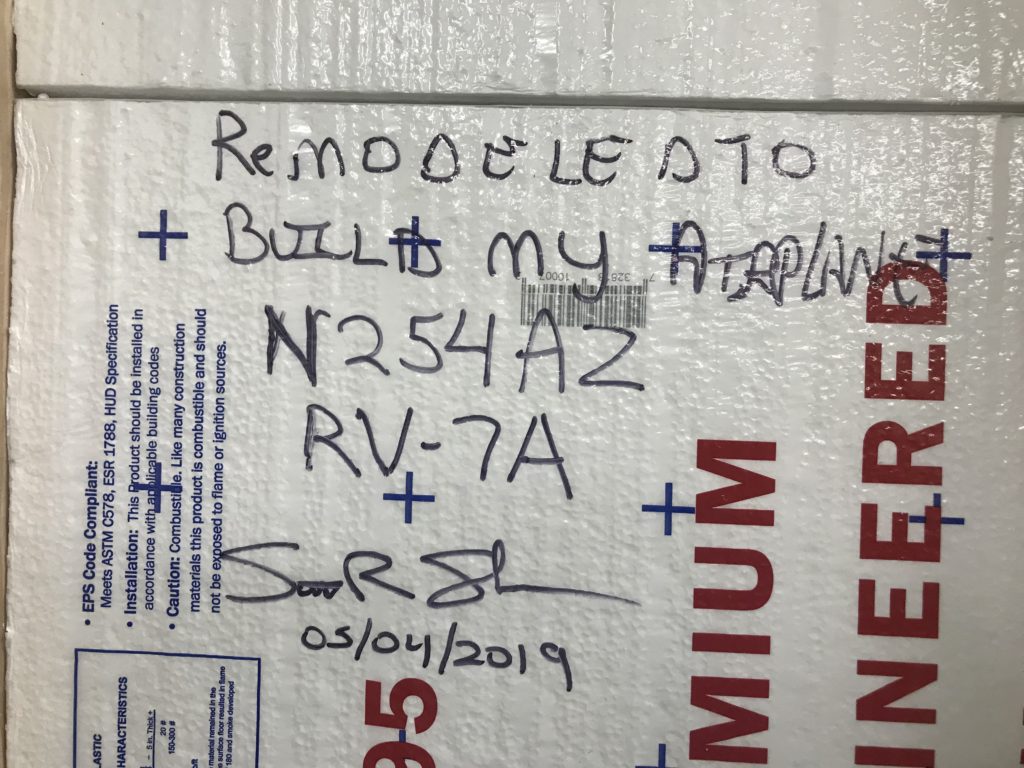

As with every other rebuild/remodel project I have done around the house, there is an “Easter Egg” style message hidden somewhere. I figure someday someone may find my hidden messages.

My new Quincy 60 Gal, belt driven compressor is due to be delivered on 8 May 2019.

Now that the shop is ready, I’m ready to move on to the tooling.